INFOBOARD

The leading production scheduling software solution

See Production Clearly | Schedule Confidently | Deliver Consistently

TECHNOLOGY

Visual Production Scheduling

infoBoard leads the manufacturing industry with planning technology that transforms complexity into clarity. This solution simplifies work organization through an innovative visual interface that production teams embrace immediately.

The intuitive planning board provides instant control over operations, allowing real-time adjustments through user-friendly graphical displays that translate complex schedules into actionable insights for everyone on your team.

infoBoard: Where production planning becomes visibly simple.

SOLUTION

A Better Way For Effective Scheduling

Boost productivity while cutting costs with intelligent scheduling that identifies conflicts, controls job flow, and ensures material availability. infoBoard seamlessly integrates maintenance, leave, and training commitments while adapting instantly to production changes.

The result: a continuously accurate production plan that keeps your entire organization—from operators to executives—aligned with reliable, real-time information.

infoBoard: Where visual clarity meets operational excellence.

INFOBOARD - EASY, IN SIX IMAGES

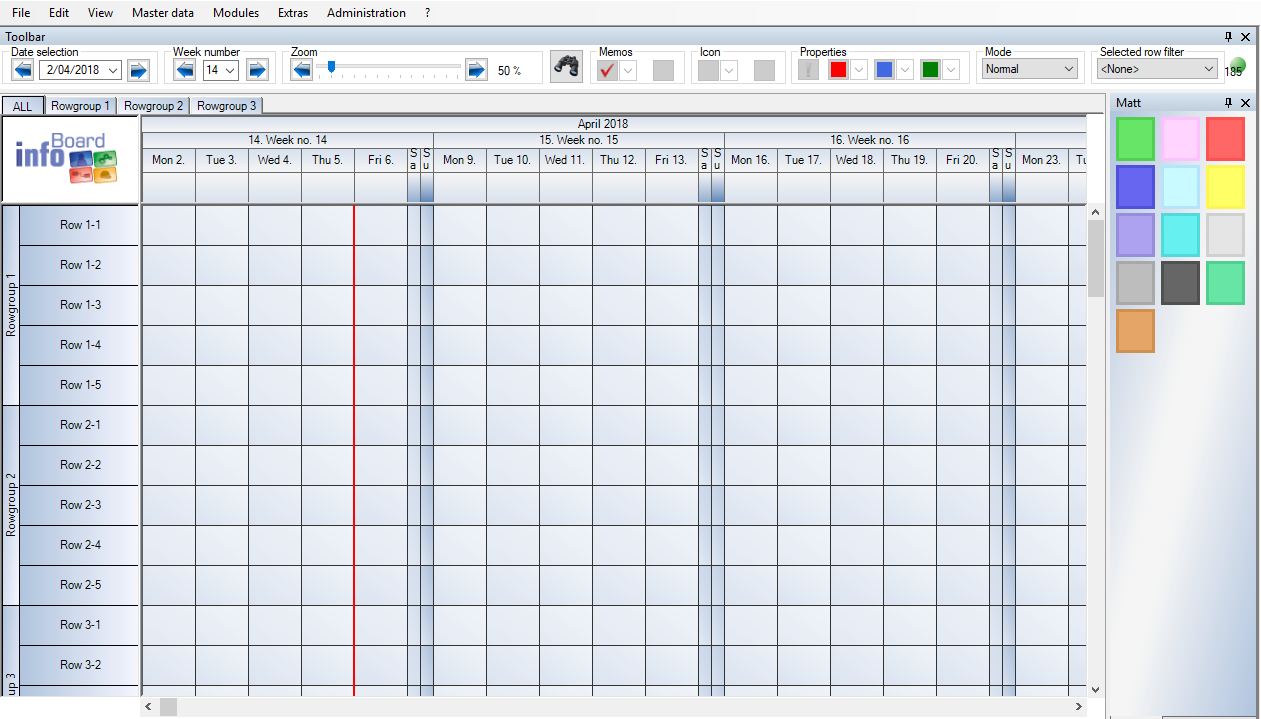

1. Add a new planning board

A new planning board, date/time across the board and resources along the side with a gallery of planning objects on the right.

![]()

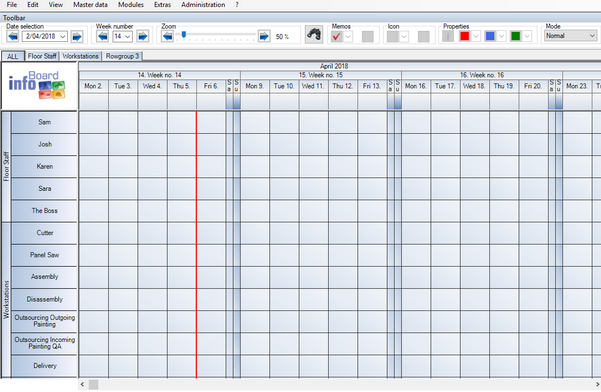

2. Add all available resources

Resources - staff, machinery, workstations are defined on the left to which jobs/tasks will be scheduled to in the planning board

![]()

3. Add workforce

Staffing can be included in planning board - assigned to production scheduling tasks, business operations (e.g. outdoor sales) or planned leave/not available for work.

![]()

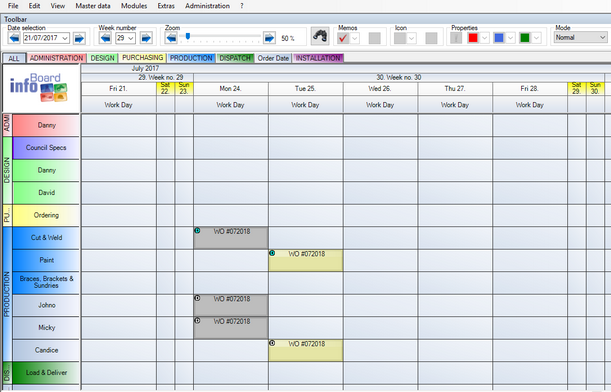

4. Add planned downtimes

Planned and unplanned downtime - e.g. machine maintenance, machine breakdown, staff annual leave, staff sick leave.

![]()

5. Add resource links (multi-dimensions)

Readily supports a job/task assignment to multiple resources - when a job/task on a workstation is affected all associated resources are also impacted.

![]()

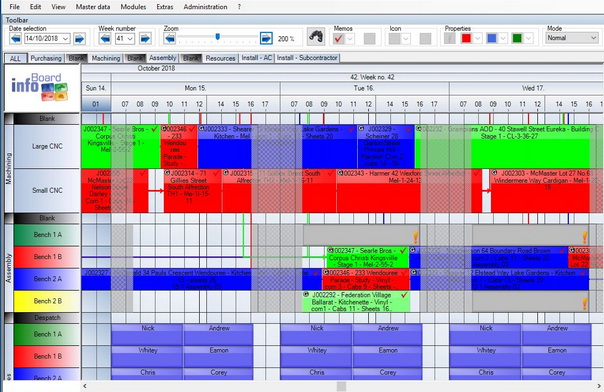

6. Production schedule is completed

The completed Production Plan/Schedule for the operations. Ideally, this must be reviewed and updated, manually or automated to reflect the latest schedule.

![]()

CASE STUDIES

H&H Cabinets

Kitchen Renovation specialists

H&H Cabinets, an HIA

Victorian Kitchen of the Year Award Winners and leader in the cabinetry and

kitchen industry, has built a strong

reputation for excellence in craftsmanship, innovative designs, and

high-quality materials.

Read

windows west

incorporating: kontrail

We manufacture windows, doors, hatches & closures.

In 2023, KONTRAIL, a respected manufacturer of watertight and weather-tight doors and hatches based in

Henderson, WA, was integrated into Windows West's operations. KONTRAIL’s products are known for their precision

engineering, durability, and ability to withstand harsh environments.

read

Metzke

We've always been here for drillers.

We always will be.

Metzke is a leading global manufacturer of premium drilling equipment for the exploration, production, and water well drilling

industries. Their reverse circulation sampling systems and breakout technologies are celebrated for their superior quality,

functionality, and reliability.

read

SQP Engineering

SQP was named and founded on three

core principles: Service, Quality & Products.

SQP Engineering, renowned for producing the highest quality

precision-crafted products, leverages state-of-the-art technology and a highly

skilled team. Their products are engineered to endure the harsh conditions of

mine sites and meet the exacting standards of the oil and gas industry.

read

HOW WE SUPPORT YOU

We Understand Your Challenges

1

Every manufacturing operation faces unique production challenges. We quickly identify your specific requirements through focused consultation, creating a tailored solution proposal that addresses your distinct needs.

We Create Your Custom Solution

2

Using insights from your operation, we build your personalized planning board from day one. This customized approach eliminates lengthy learning curves, delivering immediate benefits while serving as the foundation for our targeted training workshops.

We Evolve With Your Business

3

Implementation is just the beginning. We conduct regular reviews of your planning board usage every 2-3 months, recommending optimizations based on real usage patterns. As your business grows, we facilitate seamless integration between infoBoard and your existing systems to support your evolving needs.

Partnership in action: From implementation to integration.

About us

We are Qmani

At Qmani, we deliver Australian-built technology and quality solutions that transform how government agencies, councils, and businesses manage their assets and workflows.

As an Australian solutions provider, we combine local expertise with innovative approaches to create mobile data solutions that solve real operational challenges. Our comprehensive service extends beyond software to include enterprise-grade hosting in our world-class data-centre, complete with robust security protocols and reliable contingency systems.

We believe in partnership, not just products.

Our disciplined approach involves direct consultation, validation, demonstration, and implementation, followed by continuous software updates and dedicated support from our specialized team.

Our multi-user web solutions deliver proven, cost-effective results that grow with your organization.

Beyond our core offerings, Qmani's principals provide strategic IT consulting that aligns technology decisions with your broader business objectives.

QMANI PTY LTD

LEVEL 1, 261-267 HIGH ST, ASHBURTON, VIC 3147, AUSTRALIA

CALL +61 3 9855 2013

EMAIL info@qmani.com

See Production Clearly

Schedule Confidently

Deliver Consistently

The intuitive planning board provides instant control over operations, allowing real-time adjustments through user-friendly graphical displays that translate complex schedules into actionable insights for everyone on your team.